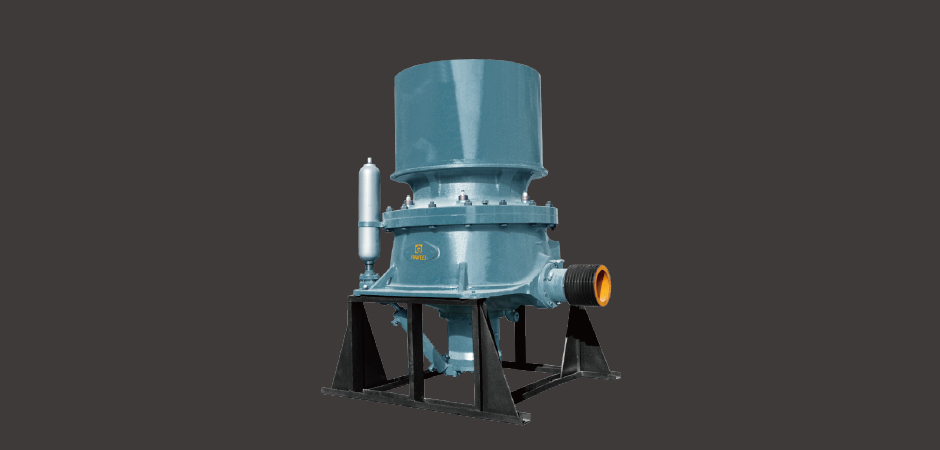

SC Cone Crusher

SC Cone Crusher Working Principle

SC Cone Crusher with hydraulic-driven system is a newly-developed stone crushing machine with high efficiency.

The electromotor leads the eccentric sleeve to rotate by the V-belt, drive shaft and drive gear. The movable cone does rotary and pendulum movement under the leading role of eccentric sleeve which makes the movable cone and fixed cone close and far away from time to time. The raw material is crushed in the crusher chamber by squeezing and striking continuously and the crushed stone are discharged from the bottom.

SC Cone Crusher Advantages

- 1. Higher efficiency and larger capacity: filler-free, more than 600t/h; 35%-60% higher than spring crusher;

- 2. Longer using time: an increase of 30%-80% than traditional crushers;

- 3. Reliable intelligent hydraulic system:high pressure to support ordinary hydraulic system;

- 4. Better cubic finished product and less useless end product in irregular shape:

- Lamination Crushing Principle

- In a crushing ratio of more than 4-30

- 5. Environment-friendly: lower noise-under 83 db, less dust;

- 6. Wide range of application suitability: 80 kinds of stone;

- 7. Various sets of models: more than 10 types;

- 8. Customized design according to your requirements;

- 9. Reliable technology: a professional design group since 1974;

- 10. Perfect customer service: composed of skilled engineers, offering professional service.

SC Cone Crusher Data

| Model | Diameter(mm) | Cavity Type | Max Feed Size(mm) | Discharge Size(mm) | Capacity(t/h) | Max Installed Power (kw) | External Dimension (mm) |

| SCH90 | 790 | EC | 135 | 10-32 | 46-128 | 90 | 1550*1575*1965 |

| C | 90 | 10-25 | 43-118 | ||||

| M | 65 | 8-16 | 36-76 | ||||

| MF | 50 | 6-13 | 29-68 | ||||

| F | 35 | 4-10 | 27-57 | ||||

| EF | 28 | 6 | 30-40 | ||||

| SCH132 | 956 | EC | 185 | 13-38 | 69-215 | 132 | 1875*1920*2400 |

| C | 145 | 13-32 | 65-197 | ||||

| MC | 115 | 10-25 | 60-180 | ||||

| M | 90 | 10-22 | 60-160 | ||||

| MF | 75 | 8-19 | 61-125 | ||||

| F | 50 | 6-19 | 45-105 | ||||

| EF | 35 | 6 | 70-90 | ||||

| SCH220 | 1150 | EC | 215 | 16-44 | 110-380 | 220 | 2100*2320*2780 |

| C | 175 | 13-38 | 100-385 | ||||

| MC | 140 | 13-32 | 95-325 | ||||

| M | 110 | 13-25 | 115-335 | ||||

| MF | 85 | 10-22 | 90-280 | ||||

| F | 70 | 8-19 | 90-235 | ||||

| EF | 38 | 8 | 100-125 | ||||

| SCH315 | 1408 | EC | 275 | 16-44 | 177-660 | 315 | 2380*2735*3265 |

| CX | 245 | 16-38 | 170-650 | ||||

| C | 215 | 16-38 | 170-640 | ||||

| MC | 175 | 16-32 | 160-552 | ||||

| M | 135 | 16-32 | 195-500 | ||||

| MF | 115 | 13-32 | 190-450 | ||||

| F | 85 | 13-25 | 195-400 | ||||

| EF | 65 | 13-22 | 210-300 |