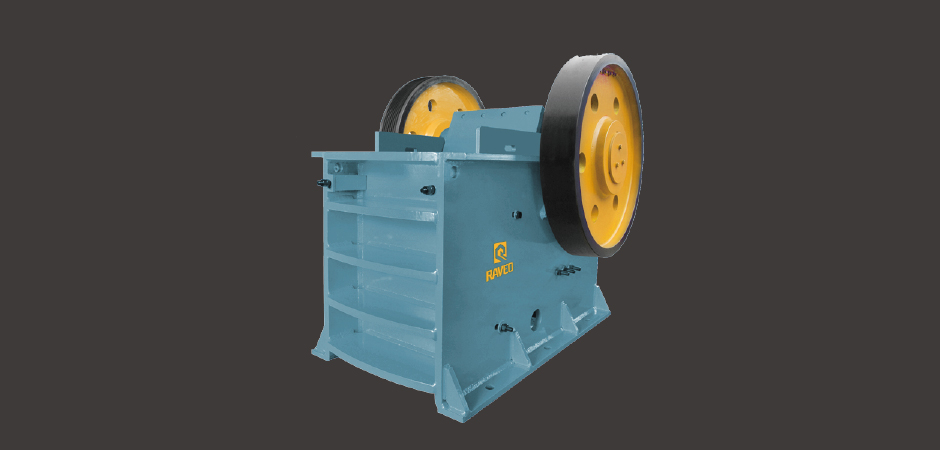

PE Jaw Crusher Introduction

PE jaw crusher is the most popular crushing equipment in industrial and mining production, and it is mainly used in intermediate crushing and coarse crushing for all kinds of materials, whose anti-pressure can reach 320Mpa. Jaw crusher is widely used in industries of mining, smelting, building, highway, railway, and water conservation, etc.As iron ore crusher, jaw crusher machine withstand extreme conditions of the mining industry. The iron ore is fed into primary crusher, usually jaw crusher and impact crusher, by vibrating feeder evenly and continuously.Jaw crusher machine acts as the first crushing machine to process iron ore.

PE Jaw Crusher Working Principle

The pe jaw crusher is driven by electromotor, through electromotor pulley, drives eccentric shaft by V-belt and scored pulley, movable jaw makes reciprocating motion by desired trajectory, crushes the materials entering into the crushing cavity consisting of fixed jaw plate, movable jaw plate and guard plate, and the finished materials are discharged through lower discharge opening.

PE Jaw CrusherFeatures

- 1. The application of world-class manufacturing processes and high-tech materials;

- 2. Integrated steel structures are used for the base of bearing;

- 3. The crushing chamber uses “V”-shaped structure, so that the feeding size equal to the nominal one;

- 4. The crushing chamber is deep and without dead zone, increases the capacity and the output;

- 5. Lubrication system is safe and reliable, convenient to replace parts, easy to maintain;

- 6. The outlet employs shim adjustment system, convenient and reliable, and increase the flexibility of the equipment;

- 7. Low noise, less dust;

Data

| Model | Feed Opening Size(mm*mm) | Max. Feed Edge(mm) | Discharge Opening Range(mm) | Capacity (t/h) | Eccentric Shaft Speed (r/min) | Motor Power (kw) | Weight (t) |

| PE-150*250 | 150*250 | 125 | 10-40 | 1-5 | 300 | 5.5 | 0.81 |

| PE-250*400 | 250*400 | 210 | 20-60 | 5-20 | 300 | 15 | 2.8 |

| PE-400*600 | 400*600 | 340 | 40-100 | 15-60 | 275 | 30 | 6.5 |

| PE-500*750 | 500*750 | 425 | 50-100 | 45-80 | 275 | 55 | 10.1 |

| PE-600*900 | 600*900 | 500 | 65-160 | 50-120 | 250 | 55-75 | 15.5 |

| PE-750*1060 | 750*1060 | 630 | 80-140 | 52-180 | 250 | 110 | 28 |

| PE-800*1060 | 800*1060 | 640 | 100-200 | 136-230 | 250 | 110 | 29 |

| PE-900*1200 | 900*1200 | 750 | 95-165 | 140-260 | 200 | 132 | 46.5 |

| PE-1000*1200 | 1000*1200 | 850 | 195-265 | 315-342 | 200 | 132 | 47 |

| PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 180 | 200 | 83.5 |