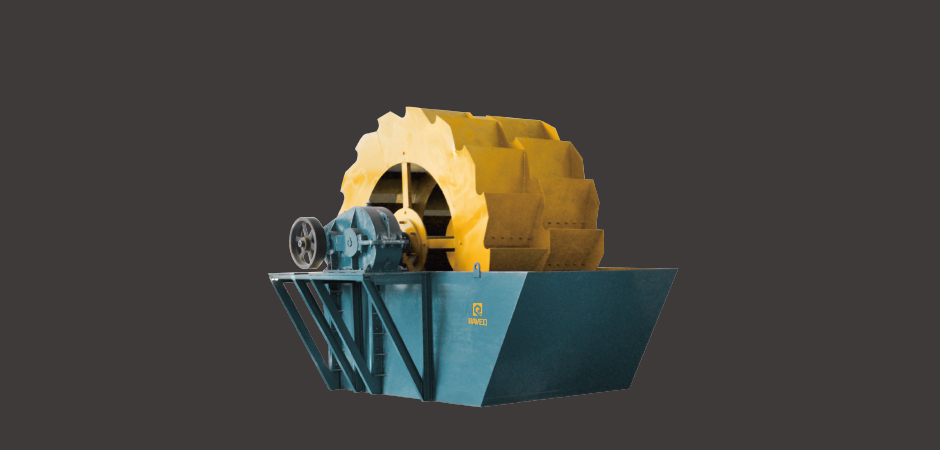

XS sand washer

Introduction:

With adopting advanced domestic and foreign technology, combining with the stone and sand industries’ real conditions and a high-efficiency sand washing device matching with sand making machine, the XS sand washing machine has unique features: high washing performance, reasonable structure, high processing capacity, low power consumption, low fine sand drain, low failure rate.XS and XL series of the sand washing machines are designed for cleaning, classifying and dehydrating of very kind of stone sand as quartz sand, with their own properties and being cooperated in use, further providing the exact and flexible measures for the clients of different requirements.

Working Principle:

The electric motor runs slowly with the impeller after decelerated by the belt, decelerator and gears wheel. The sand and stone flow into washing launder from feeding launder, rolls with the impeller, and grinds each other. The impurity covering the sand is washing away. At the same time, add more water, the strong water flow will take away waste and some low-weight wastes from washing launder. Through the above process, the washing function is finished. The clean sand and stone is lift up by vane. When it goes up slowly, the water begins to drop through the mesh and fall back in the washing launder. On one hand, water is removed from the sand and stone; on the other hand, the water can be fully used. Finally, the sand and stone goes to the out launder from the rotary impeller to finish the washing task.

Advantages:

1.Higher degree of cleanness.

2.Large handling.

3.Save water.

4.Long life and long-term without maintenance.

5.Regulating performance is good.

6.Mid-fineness sand seldom lapses out.

7.High ablution, big capacity, low consumption, long serving life.

Data:

| Model | Wheel Diameter (mm) | Selected Granularity (mm) | Production Capacity (t/h) | Power (kw) | Overall Dimension (mm) | Weight (kg) |

| XS2610 | 2600 | ≤10 | 50 | 7.5 | 3320×2125×2670 | 2680 |

| XS3016 | 3000 | ≤10 | 80 | 15 | 3810×2686×3085 | 3260 |

| XS3620 | 3600 | ≤10 | 150 | 18.5 | 4500×3206×3485 | 4300 |